CNC Automatic Load/Unload Glass Cutting Line

CNC Automatic Load/Unload Glass Cutting Line

CNC Automatic Load/Unload Glass Cutting Line

ERVIN Italian made cutting tables are AFFORDABLE and made of the utmost quality, giving you the best value in the industry. All cutting tables come with a 1 year warranty.

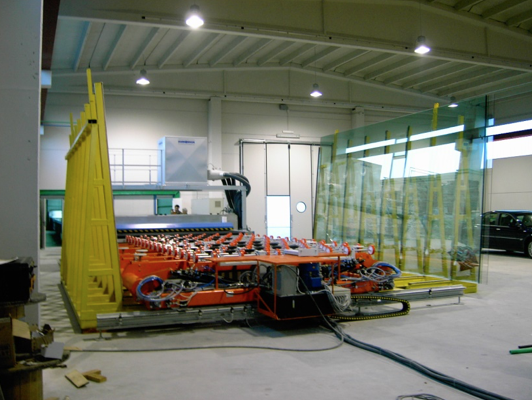

Automatic cutting line for shape glass

Automatic glass cutting line for shape cut composed by:

Fixed mono-side loading machine mod. CB/02

Cutting table model for shape cut with belts for glass transport

Breaking table mod. TCA/100

Cutting Line Overall Dimensions (LxWxH): 21000x6000x900 mm

Glass sheet dimension: 6000x3300 mm

Total Power: 21 Kw (220V and 480V power setup available)

Double-side automatic loading machine mod.

Automatic machine to load glass sheets, max dim. 6000x3300 mm. The machine is composed by N° 6 arms per side with N° 3 vacuum pads for each arm and with adjustable height. The machine is fixed and the glass sheet loading is from lateral racks on each side positioned aside the machine. The glass is laid on the machine surface and the wheels are operated by motors with inverter.

Independent vacuum pump with safety system. The loading time is about 60 sec. Electric system with the operator panel aside the machine and all the automatic operations are controlled by PLC.

Technical Data:

Glass max dimensions: 6000x3300 mm (236x130”)

Glass min dimensions: 3210x2000 mm (130x78”)

Thickness: 3-19 mm

Working height: 900±20 mm

Max glass package width: 600 mm

Air compressed: 6/7 bar

Voltage: 400 V – 50 Hz (3 phases + Ground)

Installed power: 12 Kw

Working cycle time:about 60 sec

Automatic cutting table mod.

Automatic cutting table for shape cuts X,Y,C. Fixed working plain and structure made up of electro-welded steel tubular pipes. N° 4 belts for glass transport to the breaking table. Accurately flat working plain covered of black wool felt. Powerful air cushion system. Cutting bridge made up of steel and placed transversally to the machine and it is set in motion by Brushless motors. Cutting pressure is adjusted automatically by a proportional valve in accordance with glass thickness through the software. Lubrication system for cutting tool. All the movement are controlled by CNC numerical control and the transmission is by rack and pinions. PC and cut optimization software included. Laser sensor for automatic square system and shape detection included.

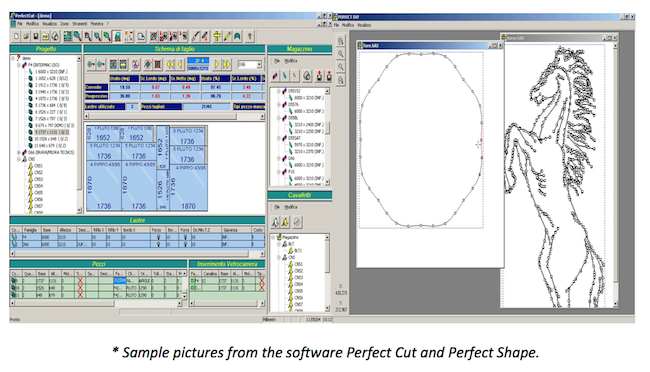

Description of the software:

The optimization software Perfect Cut includes:

Here a brief description of the content.

Perfect CAD is a CAD software specifically designed for the glass sector, with all the functions that are fundamental for glass shapes. Its main feature is its user-friendliness, despite its completeness and usefulness. The training course lasts one day only.

Perfect DXF is a limitation of Perfect CAD to DXF format import and subsequent changes to the layout, such as grinding offset, edging, edge advance, shape initial node definition, cutting direction, tool to be used (if different from the default one, e.g. for open cut) for some entities (curves or segments).

One Perfect CAD option is Perfect Spline that allows acquiring points from a carton prototype of the shape by using a laser device, a digital drafting machine or a drawing tablet and connecting points with an optimal curve, always tangent and with the minimum number of entities (arcs or segments)

Perfect Shape is a program for parametric shape management. With this software the user can create new parametric shapes that can be immediately used. One of its main feature is the correspondence between parametric and text format files, with a metalanguage geometry-oriented. The customer can change existing shapes or creating new ones by using the metalanguage. It offers the possibility of receiving new shapes via E-mail or other means and inserting them automatically in the package (by double clicking); as well as storing the shape in proprietor or DXF format and using CAD for subsequent changes to the shape.

Perfect Label is a program for professional printing of labels for the glass sector. It uses the same data as the optimizer. It allows managing different models of label (divided according to families or customers), by setting the page and defining the labels format.

The fields can be easily inserted on a model, it is possible to change font type and size. Different kinds of selection and ordering are available. It is possible to insert the company logo or to print fields with bar codes. Specific management of the fields "date" and "shape".